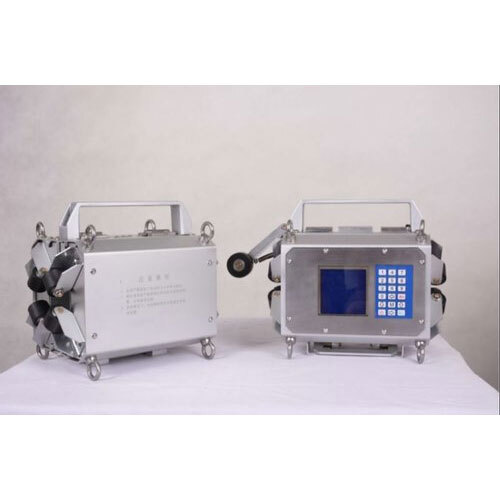

Wire Rope Inspection System

1000000 INR/Unit

Product Details:

- Color Black

- Usage Industrial

- Weight 2 Kilograms (kg)

- Product Type Wire Rope Inspection System

- Accuracy 100 %

- Control Mode Manual

- Click to View more

X

Wire Rope Inspection System Price And Quantity

- 1000000 INR/Unit

- 1 Unit

Wire Rope Inspection System Product Specifications

- Wire Rope Inspection System

- 100 %

- 2 Kilograms (kg)

- Industrial

- Manual

- Black

Wire Rope Inspection System Trade Information

- 1000 Unit Per Day

- 1 Week

Product Description

A wire rope inspection system is a set of tools, techniques, and procedures used to assess the condition and integrity of wire ropes commonly used in various industrial applications such as cranes, elevators, mining equipment, and suspension bridges. Wire ropes are critical components for lifting heavy loads and are subject to wear, fatigue, and corrosion over time, which can compromise their safety and efficiency.

The inspection of wire ropes typically involves both visual examination and non-destructive testing methods to detect any signs of wear, damage, or deterioration. Some common techniques and tools used in wire rope inspection systems include:

1. Visual Inspection: This involves a thorough visual examination of the entire length of the wire rope to identify any visible signs of wear, broken wires, kinks, corrosion, or other forms of damage.

2. Magnetic Particle Inspection (MPI): MPI is a non-destructive testing method used to detect surface and near-surface flaws in ferromagnetic materials. It involves applying a magnetic field to the wire rope and then applying magnetic particles to the surface. Any discontinuities or defects in the wire rope will cause the magnetic particles to gather at those locations, making them visible to inspectors.

3. Ultrasonic Testing (UT): UT is another non-destructive testing technique used to detect internal flaws and discontinuities in materials. It works by sending high-frequency sound waves through the wire rope and analyzing the reflected waves to identify any defects.

4. Eddy Current Testing (ECT): ECT is a non-destructive testing method that uses electromagnetic induction to detect surface and near-surface flaws in conductive materials like metal wire ropes. It works by measuring changes in electrical conductivity caused by defects in the wire rope.

5. Rope Access Techniques: In some cases, inspectors may use rope access techniques such as climbing or rappelling to access difficult-to-reach areas of the wire rope for inspection.

6. Automated Inspection Systems: There are also automated wire rope inspection systems available that utilize advanced sensors and imaging technology to inspect wire ropes quickly and accurately. These systems can provide detailed data and analysis of the wire rope condition.

Regular inspection and maintenance of wire ropes are essential to ensure their safe and reliable operation. By using a comprehensive wire rope inspection system, organizations can identify potential issues early, minimize downtime, and prevent accidents or equipment failures.

Wire Rope Inspection System Specifications:

1. Electromagnetic Induction Sensitivity: U/H>1.0v/mT

2. Display: Digital

3. Material: Metal

4. Technique: Hot Rolled

5. Use Relative Humidity: <95%

6. Use Ambient Temperature: -20 to +40 Degree

7. Weight: 2 kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free